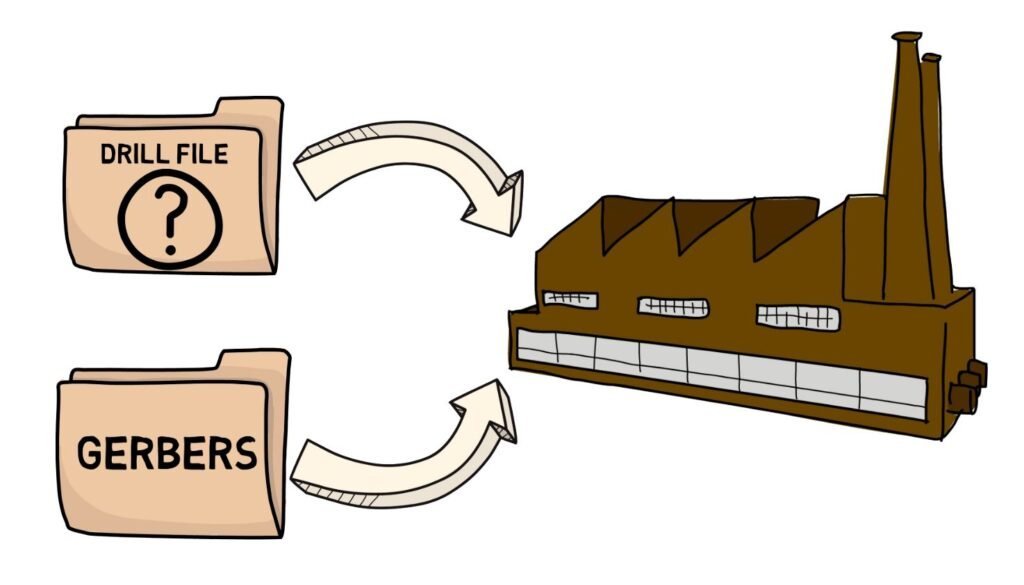

If you have never had a board manufactured, then hearing about Gerber and Drill files might sound like a foreign language. After all, can’t you just send your schematic and layout files directly to your manufacturer and let them handle the rest?

As we all know, there are a number of PCB design software out there. All with their own native file format. Imagine if a manufacturer had to keep track of every native file format from each PCB design tool, throughout all time. It would be complete madness!

Instead of relying on native file formats, every PCB design tool supports an intermediary manufacturing files, called Gerbers. These files describe the copper of every layer in your PCB in a way that a computer-aided manufacturing system can understand.

When Gerber artwork was first invented, they were used to provide instructions to a photoplotter machine that would create a picture of your PCB using light on an unexposed piece of film. These days, Gerbers are used to controls a laser plotting machine to make an image of all the traces, holes, vias on your PCB layout.

Gerber files

The trick with Gerbers is that every file you generate will be associated with a particular layer on your board layout, each with its own unique file extension. Here are the standard file extensions:

| File Extension | PCB Layer |

| .cmp | Top Copper |

| .sol | Bottom Copper |

| .stc | Top Soldermask |

| .sts | Bottom Soldermask |

| .plc | Top Silkscreen |

| .pls | Bottom Silkscreen |

Drill files

You might have noticed that one thing missing from the table, is any reference to a drill file. This is actually a secondary file that you’ll need to send to your manufacturer along with your Gerbers. The NC Drill File will be used to determine exactly where all of your drill holes are placed on your board and what size they need to be.

You might also hear of an NC Drill File being referred to as an Excellon file, which is based on the drilling and routing machines that were made by the Excellon Corporation.

Gerber formats

Another thing to remember about Gerbers is their available formats –

- Gerber RS-274D

- Gerber RS-274X.

The D format is the older standard and will use two files per layer on your PCB.

The newer X standard has done away with the two file format and contains all of the information about a layer in a single file.

Regarding having to manage your design data, this makes it a whole lot easier when you only have to keep track of one file per layer instead of two. I’d always recommend using the Gerber RS-274X format.

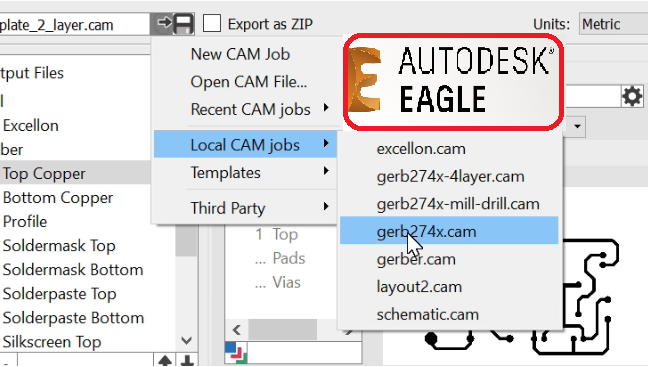

Read how to generate gerbers and drill files from Autodesk eagle https://ihrprojects.com/how-to-generate-gerber-and-drill-files-in-autodesk-eagle/.

If you liked the blog, leave a comment below. You can visit our youtube chanel https://www.youtube.com/@ihrProjects